All the benefits of a standard substation without needing a full civil-designed building. JST packaged substations include fully functional HV/LV switching, control and protection, metering, reactor compensation and more. With the added advantages of small substation footprint, flexibility to move and relocate, low capital investment, unobtrusive and attractive appearance – JST packaged substations are designed for use in high-rise buildings, residential districts, municipal facilities, industrial and mining enterprises, oilfields, ports, airports, construction site, roads, wind power plants, etc., and they will work in both indoor and outdoor settings.

| MV Equipment | Description | Unit | Parameters | |||

| Rated voltage | kV | 7.2 | 15 | 27 | 38 | |

| Rated frequency | Hz | 50/60 | ||||

| Rated current of main circuit | A | 630 | 1250 | |||

| Rated short-time withstand of the main circuit | kA | 20 | ||||

| Rated peak withstand current of the main circuit | kA | 50 | ||||

| Rated short-circuit duration | S | 3 | ||||

| Power-frequency withstand voltage, interphase, ground-to-ground and ordinary fracture/isolating fracture | kV | 32/36 | 43/49 | 95/110 | ||

| Lightning impulse withstand voltage, interphase, ground-to-ground and ordinary fracture/isolating fracture | kV | 60/70 | 5/85 | 185/215 | ||

| LV Equipment | Rated Voltage | kV | Less than or equal to 1 | |||

| Rated current of main circuit | A | 10 - 4000 | ||||

| Rated short-time withstand current | kV | 15 | 30 | 50 | ||

| Rated peak withstand current | kV | 30 | 63 | 105 | ||

| Rated current of branch circuits and number of circuit | Line A | Customized | ||||

| Reactive compensation capacity | kVAR | 0 -------- 30% | ||||

| Transformer | Rated capacity | kVA | 50 -------- 5000 | |||

| Rated voltage on the primary | kV | 3 -------- 35 | ||||

| Rated voltage on the secondary side | kV | Less than or equal to 1 (except for power transformation) | ||||

Maximum temperature: +40°C; minimum temperature: -10°C (ordinary areas) and -25°C (alpine regions)

Enclosure: Rated for outdoor use.

Ground acceleration: Suited for standard and seismic applications.

This product is intended to be installed with predefined conduit entries and an approved surface to support weight. The packaged substation will greatly reduce labor and commissioning time on-site. If any special service conditions are required for installation, inform JST of any requirements. The special service conditions (if any) shall be proposed by and confirmed prior to order placement.

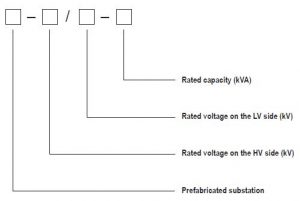

Model of the box-type substation: YB-□/□-capacity (□ depending on the rated voltage on the HV/LV side)Rated capacity: 30~3,800kVA; if the capacity is larger than 3,800kVA, consult the technicians of the Company to provide a separate scheme.

HV/LV rated voltage: The rated voltage ratio (7.2, 15, 27, 38 generally on the HV side; 0.27, 0.315, 0.4, 0.48, 0.52 and 0.69 generally on the LV side) on the HV and LV side.

Example: YB-15/480-2,500

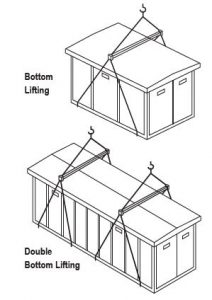

Easy to handle and easy to transport. JST packaged solutions come with standardized interfaces, such as ISO-container corners, for quick and simple fastening, lifting and rigging. All while remaining within international transport requirements and not requiring oversize transport.

The purchaser shall provide the following data related to the product during ordering:

The inclination shall not exceed 30° during product transportation. The vulnerable elements (such as the energy meters) during transportation may be removed before long-distance transportation. Anti-shock packages shall be used separately, and such elements shall be recovered after arriving at the destination. The product shall be placed at the normal usage position during transportation, and the transporting tools shall be fixed firmly to the base or the packing place. The products shall be free from movement and obvious shaking during transportation. Other positions are not allowed except for the hook at the base and the lifting rings at the top.